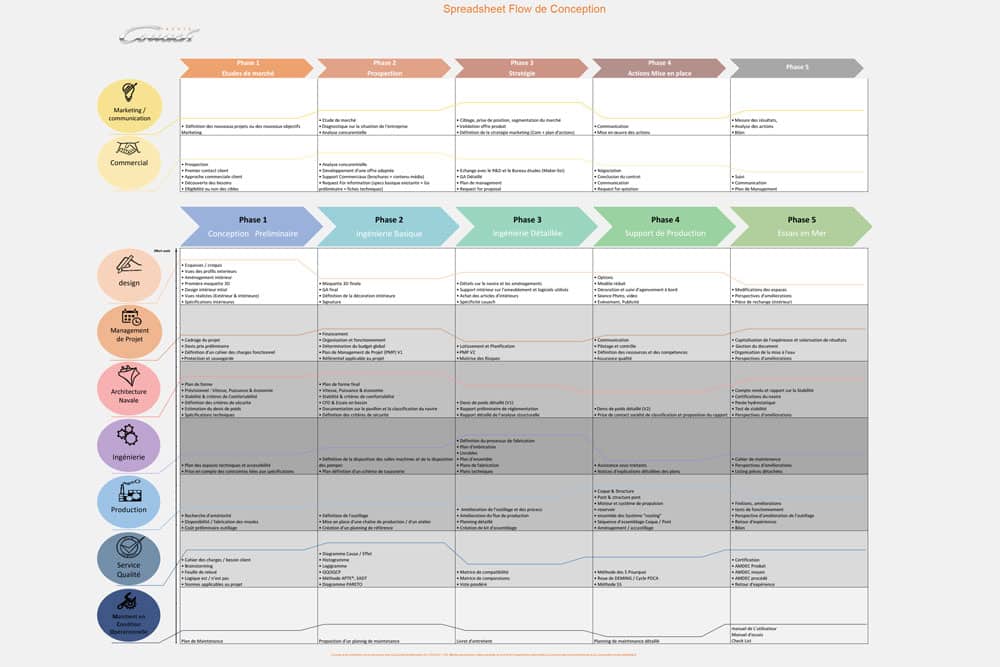

TECHNOLOGY

RESEARCH & DEVELOPMENT DEPARTMENT

In 2016, Couach created a R&D dpt. in order to work on new technologies. Recently we have developped new skills on CFD analysis and we have created a performance prediction tool. These advances have allowed us to develop better solutions and processes for our clients.

NAVAL ARCHITECTURE

Our naval architects take all the latest innovations and concepts into consideration. Allowing Couach to design new generation vessels. Qualified and equipped with powerful IT resources, these specialists are able to model boat performance even before launching.

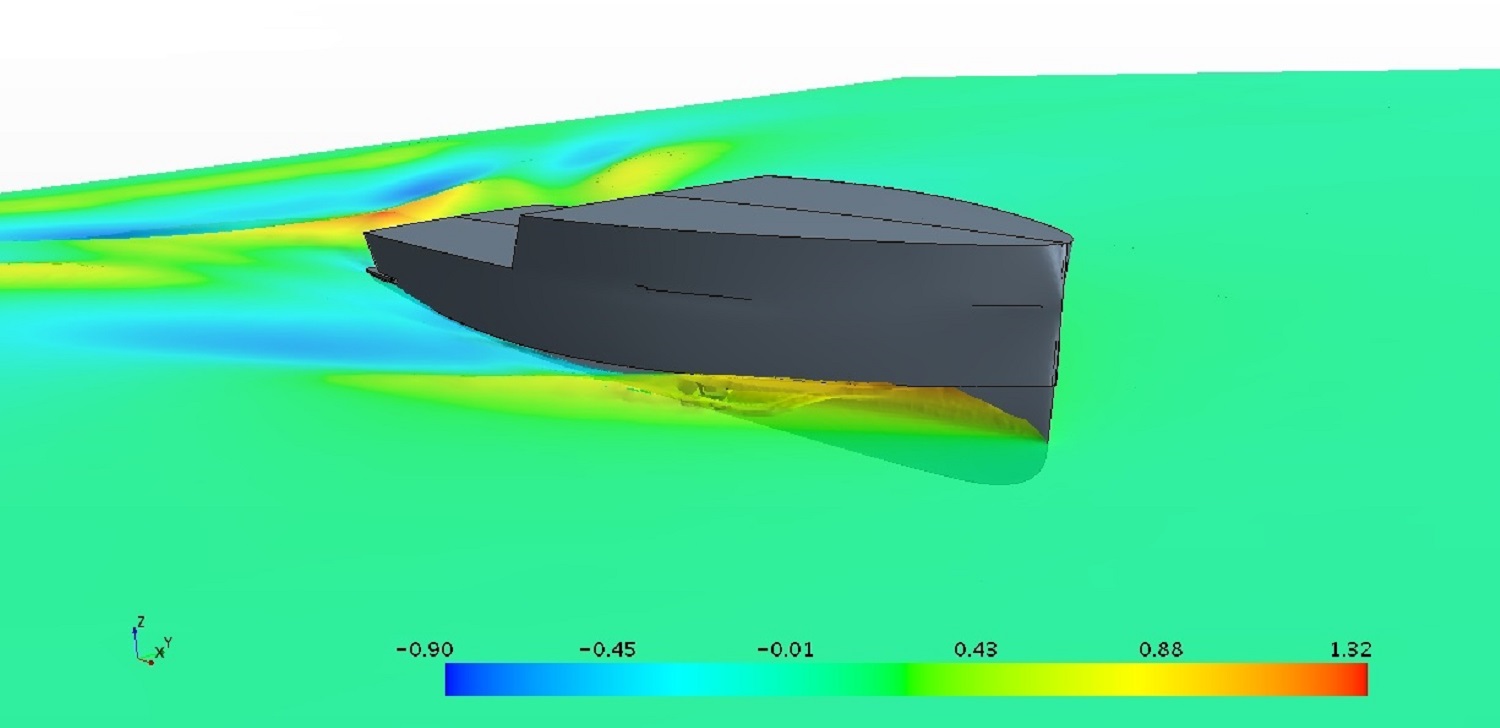

HYDRODYNAMISM

In order to optimise the boat’s performance, the hydrodynamic engineers work to reduce the thrust force that our propellers will have to produce. This modification allows us to decrease the environnemental footprint. It is necessary to make some real test associated with numerical simulation (CFD)

ENERGY EFFICIENCY

studying the interactions between the different systems, ours energy engineers optimised the boat’s efficiency thus reducing the energy consumption

STRUCTURAL ENGINEERING

We study different design processes in order to dimension and optimize the different composite elements. We work with bigger players in the regulation sector (LLOYD, DNV, ABS...). We have already validated with the help of Bureau Veritas the bonding of our composite structure which allowed us to save weight and production time.

COMPOSITE ENGINEERING

Our specialists constantly follow the evolution of innovative materials. They research, analyze, test and compare these products in order to integrate them on our boats. The goal is to improve their technical characteristics to offer better performance.

ELECTRIC ENGINEERING

We work on a IPMS (Integrated Platform Management System). It is a complete control solution for our vessels, which integrates power, propulsion, HVAC, auxiliary and damage control systems. This equipment allowed us to eliminate independent third-party control equipment, providing increased added value and support capacity to offer the best experience to our customers.

PROJECT MANAGEMENT

Good project management is very important in a product’s life. Which is why the department worked on the development of a new project matrix to work quickly and present accurate progress reports to the clients.

COMMUNICATION

Last but not least, communication is the last piece. It allows us to detail and illustrate our products in order to inform and give the desired in-depth answers.

current projects

HYBRID AS AN ENVIRONMENTAL APPROACH

In a rapidly changing market, our shipyard intends to position itself as a leader in energy development. We want to participate in the solutions of tomorrow that will be offered on board composite boats around the world. For this reason, Couach has designed the first “hybrid” 40-metre yacht that makes it possible to carry out a transatlantic crossing in perfect autonomy.

CONCEPT BOAT

The R&D Department is working on the use of new technologies. With this in mind, they decided to recycle an existing spare hull from a 17-meter military vessel to build an experimental & Labotary vessel.

OBJECTIVES

- Test of the ship’s behavior at high speed in different configurations.

- Trim test and hydraulic bench lift

- Data processing and analysis

- Acceleration measurements on structure and seats

- Recovering feedback on the ergonomics of the equipment

- Create and develop partnerships

RUDDER

The rudder is an appendix located under the boat and used to manoeuvre it. Our yachts are equipped with two each. We studied a manufacturing process that could be carried out on site and that would give superior mechanical properties.

OBJECTIVES

- Lighten the rudders which are made of steel (high density)

- Simplify the steering mechanism to facilitate maintenance

- Reduce costs and acquire knowledge

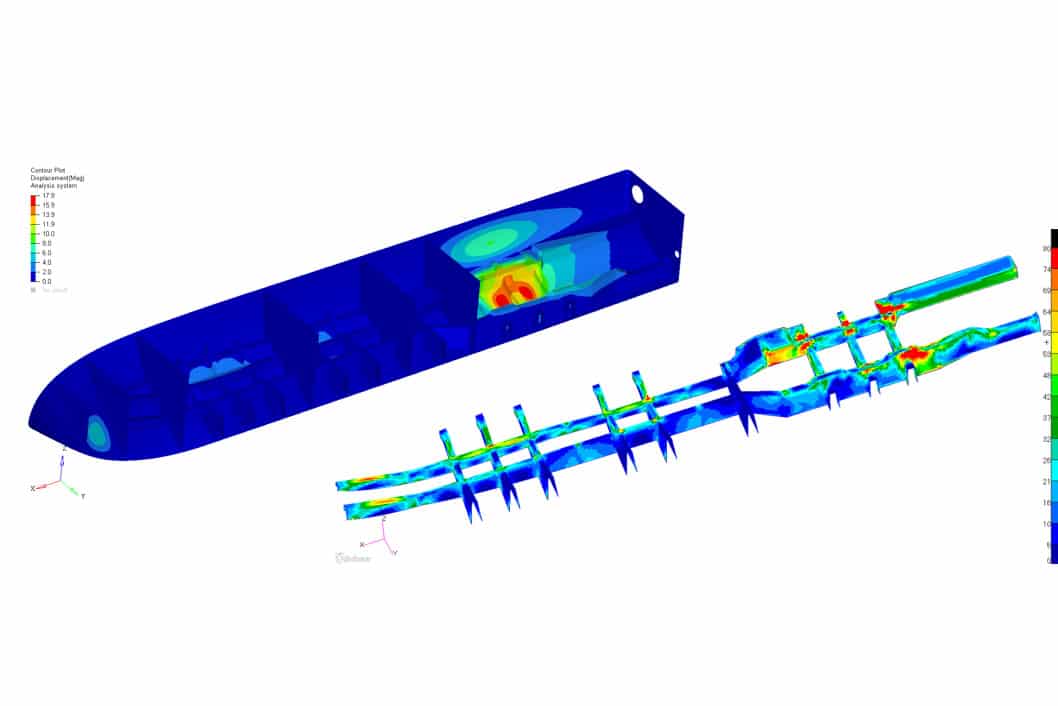

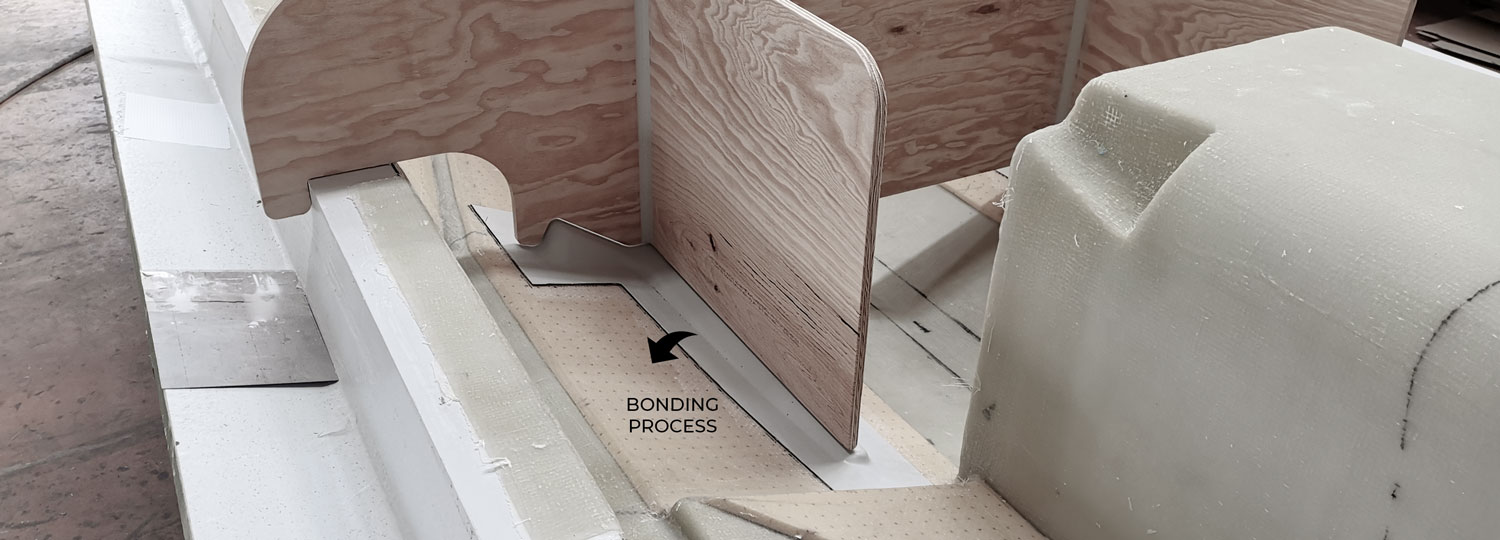

BONDING OF COMPOSITE STRUCTURE

In order to obtain high strength and low weight composite boats, R&D Department designed a new process to assemble the composite hulls and structures.

Structural bonding offers benefits to improve boat performances.

OBJECTIVES

- Apply technology to other assembly (Hull / Deck, Wheelhouse, etc.)

- Design parts to be better bonded

- Improve knowledge about structural loads on boat

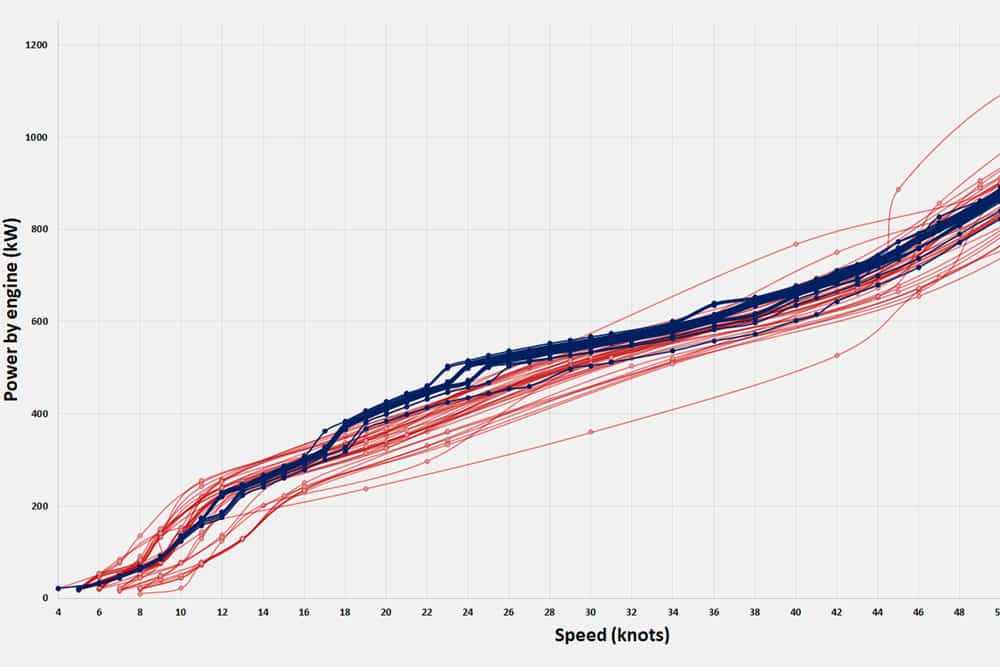

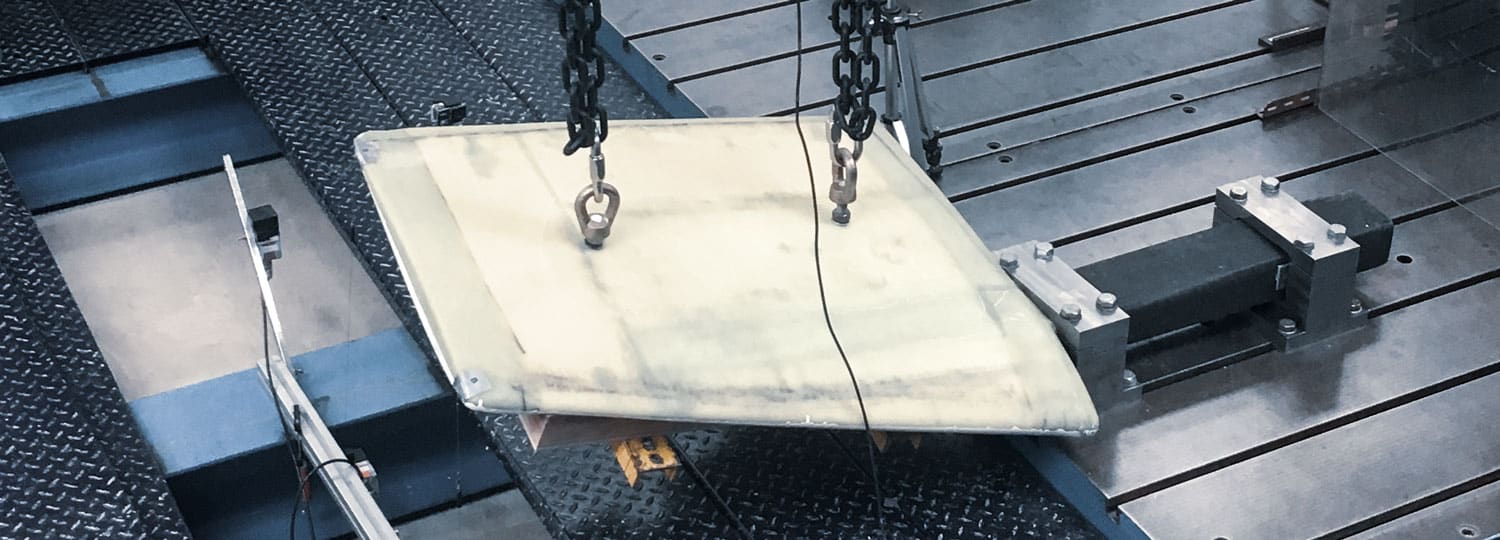

TANK TEST

The Tank Test is a tool that allows to study the behaviour of model boats that we want to build and observe their drag. Couach compares different hulls to optimize time and expense.

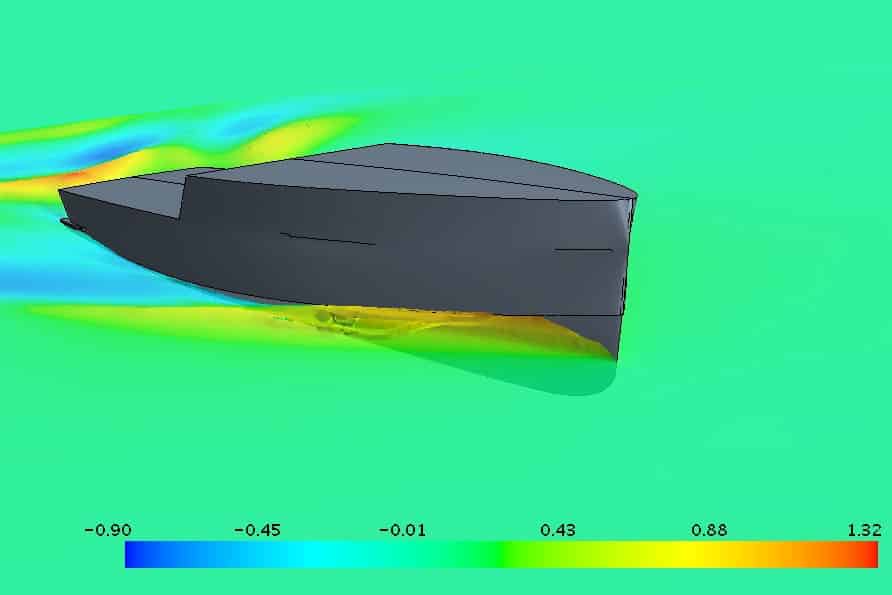

CFD SIMULATION

Naval hydrodynamics allow us to study the ship’s resistance while advancing through water. The resistance to advancement corresponds to the thrust force that our propellers will have to produce. The tests are carried out in the tank.

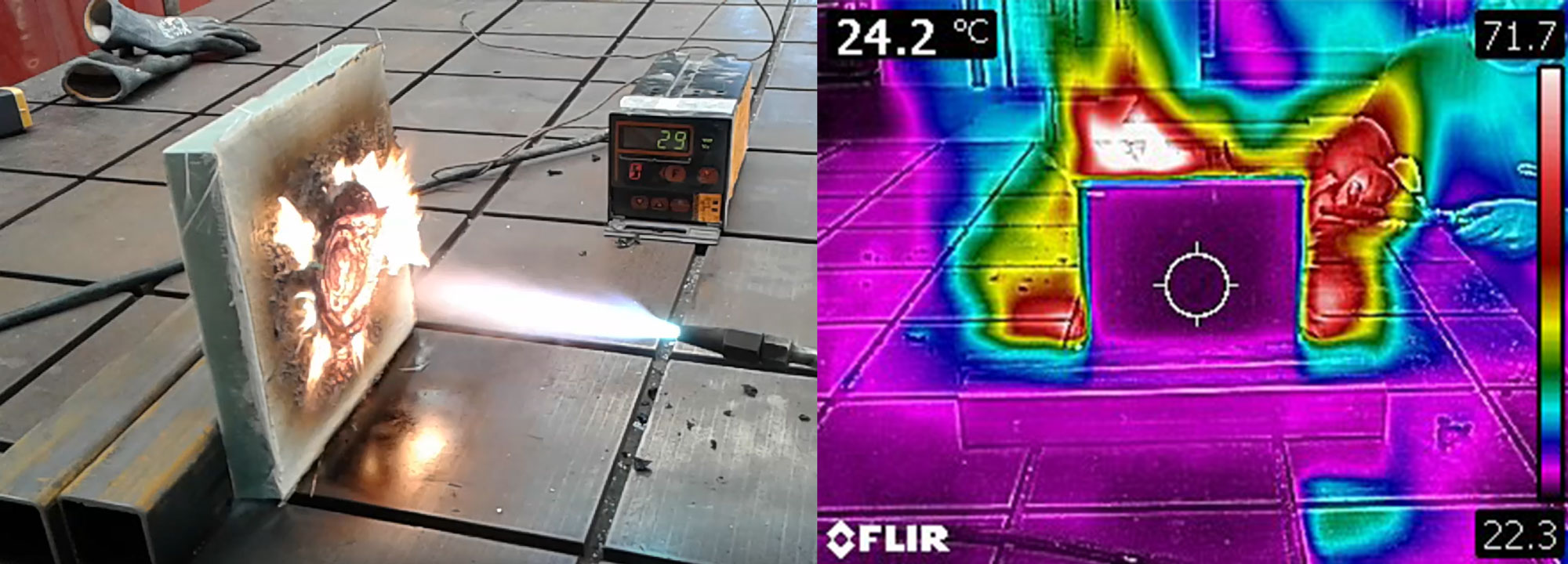

FIRE TEST

In order to replace the silica wool used in fire protection in engine rooms, Couach is testing new insulating composite materials called “intumescent” materials

OBJECTIVES

- Design, manufacture and select new fire-resistant composite materials

- Setting up a test stand at Rescoll laboratory on a small scale Fire test modeling